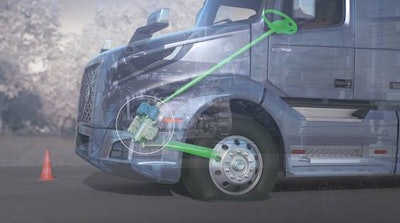

The active steering system features an electric motor (in silver) mounted on top of the standard hydraulic steering gear.

The active steering system features an electric motor (in silver) mounted on top of the standard hydraulic steering gear.Volvo Trucks North America, during a press tour at its Dublin, Va., truck manufacturing plant Thursday, introduced Volvo Dynamic Steering (VDS) – an electrically assisted hydraulic steering system designed to lessen steering input, helping reduce driver fatigue and increase road safety.

Volvo’s VDS, which debuted in Europe for the 2014 model year, will be available as an option in the Volvo VNL and VNR models in early 2020.

According to a survey of 250 drivers conducted by Volvo, 82% of respondents reported being in pain on the road, with 63% reporting they regularly visit a doctor in order to cope.

VTNA Product Marketing Manager Chris Stadler said VDS compensates up to 9 feet of torque in the steering column – the equivalent of having an extra hand on the wheel – while also eliminating vibration and offering directional stability.

The active steering system features an electric motor mounted on top of the hydraulic steering gear. Input from multiple vehicle sensors – at over 2,000 times per second – determines the appropriate steering response, “reacting before the driver can react,” Stadler said.

The self-learning system monitors the driver’s actions, environmental factors and road conditions, providing additional torque when needed and supporting driver reaction with greater control and less abrupt maneuvering.

At low speeds, the system requires 85% less effort from the driver to turn the wheel. Steering “tightens” at higher speeds, providing more directional stability.

The system’s Vehicle Stability Control leads to increased directional stability on the highway, which offers a more relaxed and safe driving experience with full control at all speeds. The Return-to-Center feature enables the steering wheel to return to the center position when the truck is in motion, making it easier to reverse the vehicle and maneuver in tight areas.

Dampening allows the steering system to filter input from the road and, based on feedback from multiple onboard sensors, improves handling and vehicle stability.

Lead/Pull Compensation offers a torque offset within the steering system to compensate for crowned roads, persistent crosswinds and other short-term conditions that can have a negative affect on handling.

If there is a system failure, Stadler said the driver is notified and can continue with conventional steering.

Testing, Stadler said, has shown that VDS has the potential to cut muscular strain by up to 30% and for some specific motions, muscular strain can be reduced up to 70%.

Stadler noted the system, which he called “a contributor to the future of autonomous development,” is also a tool for driver recruitment and retention in that it offers a more relaxed environment, is easier to maneuver at low speeds and offers full car-like steering support.

VDS will be available for order later this year with production set for April 2020.

The launch of VDS stateside is part of Volvo’s push to become “leaders in innovation,” a goal of company president Roger Alm. “We want to be ahead in technical innovation. We need to prove to our customers every day that we are better than our competitors. While other truck companies change with the times, we are committed to changing the times.”

“[VDS] is revolutionary,” added Magnus Koeck, Volvo’s vice president of marketing and brand management. “No one else is even close.”

Note: CCJ will publish a test drive recap of Volvo’s VDS system next week.