Trucking has thousands of steady well-paying technician positions available. So why can’t the industry find anyone to hire?

“People fixate on ‘techs get dirty,’ and they do, but the job is so much more than that,” says Ian Johnston, vice president of operations and marketing for Harman Heavy Vehicle Specialists. “It is becoming a far more tech-oriented job than it used to be.”

“People fixate on ‘techs get dirty,’ and they do, but the job is so much more than that,” says Ian Johnston, vice president of operations and marketing for Harman Heavy Vehicle Specialists. “It is becoming a far more tech-oriented job than it used to be.”Jim Hinton pauses to think. The Summit Truck Group service trainer has been working so long to recruit new technicians into his company’s 31-location dealer network that he can’t remember the last time Summit’s service centers didn’t have a “Help Wanted” sign in their front windows.

He guesses the signs have been posted since 2010. As for job openings, Hinton says Summit has been aware of a shrinking technician talent pool across the Southeast since at least 2006.

On the other side of the country, Ray Schmidt isn’t as certain of the timeline, but he echoes Hinton when he says technician employment has been the top priority for his company’s service department for several years.

“Hiring and recruiting techs is a weekly conversation for us,” says Schmidt, service manager for McCoy Freightliner, a company with 63 technicians across three locations in Portland and Salem, Ore. “None of our shops are operating at full capacity, and finding quality technicians to bring in is getting harder all the time.”

Hinton corroborates Schmidt’s account. He gauges Summit has at least 30 technician openings across its network.

It’s a number he hates to think about but unfortunately is learning to live with. “I don’t see an end in sight,” he says.

The worst part is that he’s right. Trucking’s technician shortage is real, and it’s intensifying.

How did we get here?

Though Hinton pegs 2006 as the year Summit first identified the shortage, the trucking industry’s path to today’s unfortunate position was not linear. A number of independently occurring factors all helped lead to the current situation.

John Pfennig Jr., Navistar‘s director of training delivery and recruitment, says one contributing aspect of today’s shortage is rooted in the past. The trucking industry has been led by one generation for decades, and that generation is aging out of the workforce. There aren’t enough working Baby Boomers to cover trucking’s job openings anymore.

“I think for a long time, no one ever measured the generational population of the technicians in our industry,” says Pfennig. “I don’t think we ever realized how many of our technicians were Baby Boomers until they started retiring. That kind of caught us off guard.”

Homer Hogg also subscribes to this theory. Presently TA/Petro’s director of technical service, Hogg entered the trucking industry as a service technician in the early 1980s when technician applicants were plentiful. He says many of his first colleagues were close to him in age, and as he advanced up the corporate ladder, he watched as his contemporaries rose with him or stepped into his previous positions.

Hogg says today’s shop floor population is much different. Boomer-aged veteran technicians hold most management roles, but the workforces they lead are increasingly Generation X and Millennials. And unlike Hogg’s generation, which gravitated toward technical jobs as a path toward a steady stable career, he says new entrants to the workforce appear to view that career choice with ambivalence at best. The fathers who powered trucking’s service channel for decades are retiring, and their sons are uninterested in following in their footsteps.

“I think it is very clear that the generations we see coming into the business today are different from those of us who have been doing this for a while,” says Hogg.

The trucking industry has been led by one generation for decades, and that generation is aging out of the workforce, says John Pfennig Jr., Navistar’s director of training delivery and recruitment.

The trucking industry has been led by one generation for decades, and that generation is aging out of the workforce, says John Pfennig Jr., Navistar’s director of training delivery and recruitment.Trucking also has become a victim of its own success. Freight activity and tonnage have grown progressively since the Great Recession. Medium- and heavy-duty truck populations are on the rise. Fleets and their customers are relying on trucks to move more goods than at any point in North American history.

But with that customer reliance also has come elevated customer expectations and a surge in consumer technology. Today’s economy is built on same-day, two-day and overnight shipping. Downtime has shifted from an unfortunate but accepted reality in trucking to a legitimate dirty word. Trucking is outgrowing its service channel.

“The economy is very good right now, and I think that puts a lot of pressure on us as service providers,” says Charlie Nichols, general manager of Calvert City, Ky.-based TAG Truck Center. “We recognize that technicians are critical. Without them, the whole infrastructure of our economy kind of collapses.”

Service businesses throughout the industry have responded appropriately to this growth, raising technician wages and investing in equipment and training to improve their productivity. Yet even with these investments, trucking’s technician shortage has swelled.

A December 2018 report by the Tech Force Foundation states the heavy-duty diesel service business is expected to require more than 4,300 new technician positions this year. Coupled with a replacement demand projection of more than 25,000 positions due to retirements, employment changes and other factors, the trucking industry needs to hire nearly 30,000 heavy-duty truck technicians this year, the report says.

U.S. Bureau of Labor Statistics’ numbers aren’t any better. The agency estimated earlier this decade there will be a 9.2 percent increase in the need for heavy-duty service technicians and an 8.6 percent increase in the need for truck and bus technicians and diesel engine specialists in 2022 from 2012 levels.

What was once a nuisance has become a four-alarm catastrophe.

Tackling the issue

The trucking industry has been led by one generation for decades, and that generation is aging out of the workforce, says John Pfennig Jr., Navistar’s director of training delivery and recruitment.

The trucking industry has been led by one generation for decades, and that generation is aging out of the workforce, says John Pfennig Jr., Navistar’s director of training delivery and recruitment.How will the trucking industry solve this growing conundrum? OEMs, dealers and independent service providers actively hiring and recruiting technicians in the market say the shortage has become too big to ignore. But while those same professionals also believe no simple solution exists to swiftly solve the service channel’s biggest problem, they say the industry isn’t without options.

By better understanding how a career as a heavy-duty diesel truck technician is perceived, both within the trucking industry and by the general population, trucking’s service channel may better identify recruitment and retention initiatives that will appeal to the demographic groups most likely to apply for, accept and enjoy a career as a technician.

“It’s time to understand the challenges facing [our] organizations and look into what is driving those challenges,” says Hogg. “Our labor pool is shrinking. We have to start looking beyond our normal hunting ground.”

If there’s one consensus within trucking regarding technicians, it’s that the profession is poorly perceived by those outside the industry. The degrading “grease monkey” stigma that plagues the automotive service channel is doubly damaging in trucking, where the equipment is larger, heavier and often dirtier.

Schmidt says all too often when attending educational career fairs at high schools and technical schools as part of his recruiting responsibilities, he will interact with a student or parent who never considered becoming a technician because they think it’s dirty low-paying work.

“It’s not like that at all,” he says. “If you’re working on a truck, sometimes you can get dirty, sure, but it’s not like that all the time.”

“Being a diesel technician is not a sexy job, I get that,” says John Devany, general manager of Fresno, Calif.-based Betts Truck Parts & Service. “But that doesn’t mean it isn’t a good job. The perception that what we do is big and scary is wrong.”

Devany says the reality is quite the opposite. Betts makes significant investments each year in diagnostics equipment and computer-based service tools to maintain heavy vehicles that become more technologically advanced with each passing year.

“A lot of kids today are growing up on tablets and computers, and that’s our future,” says Devany. “What used to be about tribal knowledge is now becoming more of a white-glove environment.”

“People fixate on ‘techs get dirty,’ and they do, but the job is so much more than that,” says Ian Johnston, vice president of operations and marketing for Harman Heavy Vehicle Specialists. “There is a ton of problem-solving and critical thinking as well. It is becoming a far more tech-oriented job than it used to be.”

“We stopped saying mechanic for a reason,” adds Hinton.

Meanwhile, the contemporary high school experience isn’t doing vocational careers any favors, says Nichols. TAG Truck Center has a partnership with a local community college in which high school graduates can enroll in the school’s heavy truck program, receive financial support and real-world experience with TAG while in school and then have a job waiting for them when they complete the program in two years.

Nichols says the success rate of hiring students who enter the program is great. The challenge is getting them to sign up in the first place. He says all too often his pitch for the program is met with apprehension from high school administrators, counselors and parents.

“There is a very big misconception in our country that every kid needs to go to a four-year college,” he says. “I don’t believe that’s the case. A four-year school is not the holy grail for everybody.”

Russ Dunnington knows this all too well. As diesel instructor and department chair at Portland Community College, Dunnington visits high schools multiple times per month to recruit potential students to his program. His program – which has partnerships with McCoy Freightliner, Daimler Trucks North America and other area service shops – has an incredible graduation and placement rate for its students.

But PCC’s success doesn’t always translate to its audience. Dunnington says his school visits yield one new PCC applicant on average and that his program remains frustratingly under capacity.

“I get emails and calls from [service providers] every day begging me for students [to hire],” he says. “I only have so many.”

What about pay?

Fresno, Calif.-based Betts Truck Parts & Service makes significant investments each year in diagnostics equipment and computer-based service tools to maintain heavy vehicles that become more technologically advanced with each passing year.

Fresno, Calif.-based Betts Truck Parts & Service makes significant investments each year in diagnostics equipment and computer-based service tools to maintain heavy vehicles that become more technologically advanced with each passing year.Those in the service channel say that while the parental dream to send one’s child to college is admirable, college is more than private institutions and land grant universities. Vocational programs such as PCC’s offer students a path to an associate’s degree and more relevant professional experience and earning potential than many bachelor’s degrees.

That latter point is another one the trucking industry needs to better publicize, says Nichols. The heavy-duty diesel technician space is well funded. Good technicians stand to earn a good living.

According to a 2018 survey of technicians in four industries (heavy truck, agriculture, construction and automotive) by Randall-Reilly, publisher of Commercial Carrier Journal and Truck Parts & Service, nearly 40 percent of heavy-duty truck technicians claimed to be earning at least $60,000 per year. Nearly half of those same responders claimed to be earning more than $70,000 annually.

Also, during a speech at the 2019 American Truck Dealers Show, ATD Chairwoman Jodie Teuton, vice president of Kenworth of Louisiana, noted the average truck technician salary at a dealership in 2018 was $61,000.

Says Nichols, “There are so many kids today who graduate from college and can’t get a job. You see them working in retail for not much money at all. They could be working for us making $50,000 to $70,000 a year plus benefits, but they have no idea we pay like that.”

Randall-Reilly’s survey supported Nichols’ claim, as truck technician responders stated they overwhelmingly receive health insurance (92 percent), paid holiday leave (83 percent) and 401(k) and/or IRA opportunities (83 percent) through their employers.

That earning discrepancy is something Meritor tries to bring to the forefront when interacting with young people through its partnership with Skills USA, says Peter Adair, technical training manager. The commercial vehicle supplier has supported Skills USA’s heavy truck technician education program for years through volunteer assistance and financial support.

Adair says students are eager to learn about Meritor’s online curriculum and virtual educational library, but when the topic of compensation comes up, that’s when heads really start to turn.

“I joke ‘Maybe I need to be a technician again,’ ” Adair says.

That’s another part of the issue, says Hinton. The trucking industry is filled with white-collar professionals who started their careers in the shop. The lure of new opportunities and leadership roles moved them up the corporate ladder, but the roles and salaries they exited still remain. In time, so too will their current roles, as trucking’s employment shortage is not limited solely to service bays.

Unfortunately, those career advancement opportunities are another source of employer-to-employee disconnect.

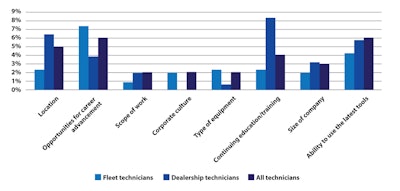

When asked Randall-Reilly’s survey question regarding career advancement potential, only 29 percent of heavy truck technicians, and 28 percent of all technicians, answered that they have a “clear career path at my current employer.” Conversely, 24 percent of truck technicians said a career path exists but has not been established by their current employer. Another 20 percent answered that “someone would need to leave or retire for me to advance.”

Those already fighting the technician shortage say these misconceptions are just another hurdle the industry needs to clear. A national movement supported by trade organizations and/or the OEM community seems the most likely effort to drive real change, but at this time no program exists. As such, those in the service channel say they will continue doing what they can individually to create awareness and promote the career opportunities found in their marketplace.

“We do a good job when we’re presenting our case to a high school student and their parents,” Schmidt says. “I think those conversations can still be sort of eye-opening to them. Big picture, we don’t do that as well as an industry.”

Johnston agrees. “At the grassroots and local levels, we still have that ability to develop relationships with students and vocational schools to begin to change the perception of these careers,” he says.

Click here to download the Randall-Reilly technician wage survey

TARGETING TECHNICIANS

Part 1: Trucking industry faces major shortage, opportunities for diesel mechanics

Part 2: Why trucking must change its technician recruitment practices

Part 3: Investment in your business can help retain your best technicians