Note: This is the second in a series that looks at the diesel particulate filter and maintenance best practices that an impact its lifecycle. The first installment, "Diesel coolant heaters boost DPF performance, reduce engine wear" can be found here.

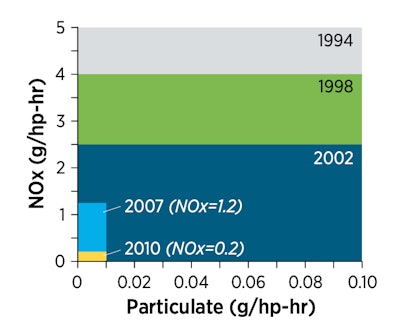

Biodiesel and renewable diesel are often marketed as convenient drop-in fuel solutions for lowering emissions. They’ve also been shown to improve diesel particulate filter performance.

In addition to significantly cutting greenhouse gas emissions, both fuels emit lower particulate matter during combustion. Less particulate matter equates to less back-pressure buildup in DPFs and fewer regeneration (regen) cycles.

“Biodiesel burns so much cleaner that you’re reducing that particulate matter by somewhere in the neighborhood of 50 to 60%,” said Colin Huwyler, CEO of Optimus Technologies which produces the Vector System, a fuel heating solution that enables diesel engines to run on 100% biodiesel, or B100, in cold climates.

“The amount of soot that actually goes into the particulate filter is dramatically less (with biodiesel)," he said, explaining that lower soot build up results in less wear and tear as well as less backpressure on the engine, which increases operating efficiency. "There’s this whole cascading benefit that comes from the higher combustion index, the cetane and the cleaner burning combustion that occurs with biodiesel.”

According to the U.S. Department of Energy, U.S. Department of Energy

According to the U.S. Department of Energy, U.S. Department of Energy