Premature air filter replacement wastes money and neglecting to replace a filter at the right time can lead to premature engine wear.

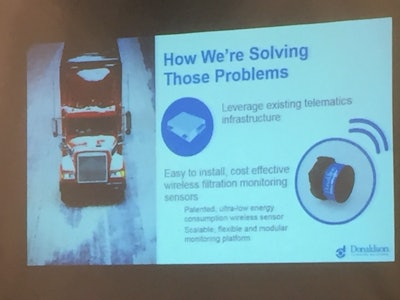

To help curb waste and extend engine life, Donaldson introduced its new Filter Minder at the 2019 Technology & Maintenance Council (TMC) meeting today in Atlanta, Ga. The wireless device equipped with sensors detects air pressure and temperature to help determine actual air filter condition. Fleets that routinely replace air filters regardless of condition stand to lose money.

“There’s a tremendous amount of money going to waste,” Nathan Zambon, director of Fleet Minder, said.

Filter Minder

Filter MinderConversely, filters that are not replaced soon enough can lead to engine damage.

“Filter service performed too early is inefficient and service performed too late can damage equipment, cause unplanned downtime and raise operating costs,” Zambon said. “Maintaining the filtration system at the optimal time best protects the engine and drives down total cost of ownership.”

Filter Minder technology provides:

- Wireless, simple installation in just minutes per truck;

- No upfront hardware costs and low monthly subscriptions;

- Patented low-energy sensors that conserve power and extend battery life;

- Filtration insights for an entire fleet of trucks consolidated into a dashboard view;

- Clear insights and customized alerts by text, phone, email or dashboard; and

- A scalable platform that can expand to monitor fuel, lube and hydraulics filters—additional applications coming soon.